Choosing the Right Custom Box: A Guide to Corrugated Styles and Strength

The corrugated box is the backbone of your supply chain, but choosing the right one can feel overwhelming. Beyond simple protection, the box style, material thickness, and strength rating are critical factors that directly impact your costs, shipping efficiency, and customer experience.

This blog guide simplifies the technical elements of custom corrugated boxes and shows how MDM Packaging & Design helps you find the perfect fit.

Understanding Box Measurements

Before selecting a style, you must know your measurements. Box dimensions are always calculated using the inside dimensions to ensure a product fits securely.

The sequence is always: Length (L) x Width (W) x Depth (D) / Height (H).

- Length (L): The longest side of the rectangular opening.

- Width (W): The shorter side of the rectangular opening.

- Depth (D) or Height (H): The side perpendicular to the opening.

Essential Corrugated Box Styles

Corrugated boxes come in various standard and custom types, each tailored for specific functional or logistical needs:

| Box Style | Description & Use Case | Key Benefit |

RSC (Regular Slotted Container) |

The most common shipping box. All flaps meet in the center when folded. | Efficiency: Highly cost-effective and streamlined for shipping. |

HSC (Half-Slotted Container) |

Similar to an RSC but open on one end. | Access: Allows quick access to contents; often used as covers or trays. |

FOL (Full Overlap Slotted Container) |

Flaps completely overlap each other, creating a double-layer on the top and bottom. | Durability: Used for heavy-duty applications like machinery and automotive parts. |

Die-Cut Boxes |

Custom-designed cartons requiring a specialized cutting die (no standard flaps). | Customization: Ideal for e-commerce, retail, and complex unboxing experiences. |

Telescoping Boxes |

Two separate pieces (a top structure slides over a bottom structure). | Flexibility: Great for large, long, or oddly shaped items like pipes or appliances. |

Corrugated Material: Walls and Flutes

The material itself dictates the box’s protective strength, stacking ability, and print quality.

1. Wall Construction

The wall refers to the number of corrugated sheets used:

- Single-Wall: One corrugated sheet between two flat sheets (linerboards). Durable and widely used for everyday packaging.

- Double-Wall: Two corrugated sheets and three linerboards. Provides extra protection and rigidity, ideal for packaging and stacking heavy items.

2. Flute Size

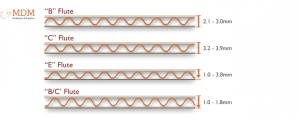

The flutes are the wavy sheets that define the corrugated board and provide cushioning and stacking strength. Common sizes are labeled A, B, C, E, and F.

| Flute Size | Key Characteristics | Best Use Case |

| C Flute | Most popular, excellent stacking and cushioning. Thicker. | General shipping boxes and product protection. |

| B Flute | Lower profile, excellent crush resistance. More rigid. | Smaller boxes, food packaging, and high-quality printing. |

| E Flute | Very thin, largest number of flutes per foot. | Retail packaging and high-quality printing (smooth surface). |

3. Strength Tests

Two tests measure the strength of the board required for safe shipping:

- Bursting Test: Measures the force required to puncture the board, indicating its ability to withstand internal and external pressure.

- Edge-Crush Test (ECT): Measures the force required to crush the board’s edge, which predicts the box’s overall compression strength (critical for stacking).

Pro-Tip: Always start with the maximum weight of your contents to determine the minimum required Edge-Crush Test (ECT) rating for your corrugated material.

How MDM Packaging & Design Ensures the Right Box for You

Digging through box styles, flute sizes, and strength ratings is complex. The optimal solution is never a compromise between aesthetics and protection—it must achieve both efficiently.

At MDM Packaging & Design, we specialize in simplifying this complexity to help you find the exact custom boxes for your needs. We don’t just sell standard RSCs; we serve as your engineering partner. We start by analyzing your product’s weight, fragility, retail environment (if applicable), and your shipping method to determine the perfect balance of box style, flute type, and required ECT strength.

Whether you need a heavy-duty FOL for industrial equipment, a high-graphic E-flute die-cut box for a premium e-commerce brand, or custom partitions and pads to protect internal contents, our team guarantees you receive a structurally sound and cost-effective solution.

Would you like us to help you determine the specific box style and material strength required for your product?